Please note that we are selling factory direct products. All our products are 100% brand new in manufacturers packaging.

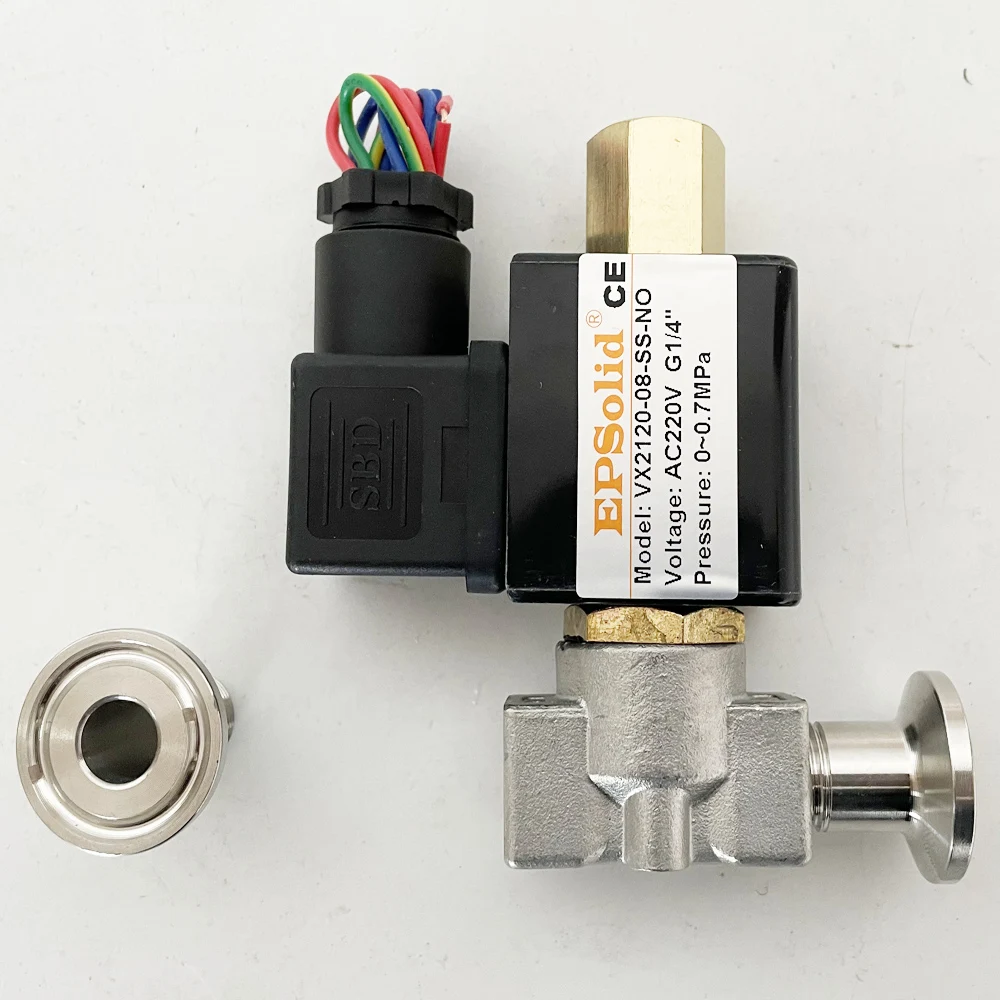

G1/4" Stainless Steel Body Normally Closed

2 Way Solenoid Valve Silicone Gel Rubber Oil Acid

Code Option

Thread Option: G and NPT

Standard Voltage Option: DC12V,DC24V,AC110V,AC220V

Material Option: Stainless Steel

Oil Seal Option:VITON

Descriptions | VX2120-08-SS-NC | ||

Port Size | G1/4 | ||

Orifice Size(mm) | 3 | ||

CV Value | 0.2 | ||

Type | Normal Closed | ||

Way Position | 2/2 Way | ||

Material of Body | Stainless Steel | ||

Material of Pin | Stainless Iron | ||

Material of Spring | Stainless Steel 304 | ||

Material of Seal | High Quality NBR and Silicone Gel | ||

Motion Pattern | Direct Drive | ||

Working Temperature | -5-100C Degree | ||

Working Pressure | Water/Air/Gas: 0~1.0Mpa | ||

Voltage | AC110V,AC220V,DC12V,DC24V,AC24V | ||

Voltage Range | ±10% | ||

Liquid | Water Oil Gas Air | ||

Coil | DIN type with Wires | ||

Description:

Two position, two way, normal close switch, magnetic solenoid water valve.

it is a good choice when the horizontal tube keep upward.

Used to control automatically the liquid and gas in the pipeline.

QA: WHY THE VALVE COULD BE SUCKED BY A MAGNET?

Some people often think that the magnet is used to test the quality of stainless steel. The magnet is not attractive, non-magnetic and genuine; If it is magnetic, it is considered to be a fake. In fact, this is an extremely one-sided, impractical and wrong discrimination method. Generally speaking, stainless steel has magnetic and non-magnetic. Austenite type is non-magnetic or weakly magnetic, such as 201, 202, 304, 316, etc; Martensite or ferrite is magnetic, such as 430, 420, 410, etc. However, due to component segregation or improper heat treatment during smelting, there will be a small amount of martensite or ferrite in Austenitic 304 stainless steel. In this way, 304 stainless steel will have weak magnetism. In addition, after cold working, the microstructure of 304 stainless steel will also be transformed into martensite. The greater the cold working deformation, the more martensite transformation, and the greater the magnetism. Like the stainless steel wire of the same batch number, it is made into a straight support without obvious magnetic induction, but when it is bent into a rectangle or circle, it will produce some magnetism due to large cold bending deformation, especially in the corner part. In order to eliminate the magnetism of the above 304 stainless steel, the stable austenite structure can be restored by high temperature treatment, so as to eliminate the magnetism. In particular, the magnetism of 304 stainless steel caused by the above reasons is not at the same level as that of other stainless steels, such as 430 and carbon steel, that is, the magnetism of 304 stainless steel is always weak.

IF u need Coil and Fittings for this valve,pls click follow picture

IF u need Clamp,pls click here

IF u need Chucks,pls click here

IF u need Normally Open Valve with Thread Chuck,pls click here

IF u need Coil for this valve,pls click here

IF u need Fittings for this valve,pls click here

General purpose 2way direct acting and semidirect lift acting valves.

Common applications include water, oil (below 20cst), air, gas, freon, *vacuum, weak acids & alkali.

Available in a body/seal material of brass/NBR or stainless steel/viton.

The coil has an adapter with screw terminals for wire leads.

Simple connect wires to the adapter and plug right into the coil for operation.

Adapters can be removed from the coil for maintenance with no need to detach wires.

Brass/NBR valves are suitable for water, hot water, gas, air, non-corrosive oils and freon.

Stainless Steel/Viton valves are suitable for hot water, acid, alkali, chemical salt, oils and hydrocarbon.

Direct Acting: These valves close or open completely on their own.

This means that they can block the flow of fluid in both directions.

SemiDirect Acting: These valves can only stop flow in one direction.

There is an arrow located on the valve body showing the direction of flow in which it blocks.

In order to prevent backflow when the valve is closed, a check valve must be installed.