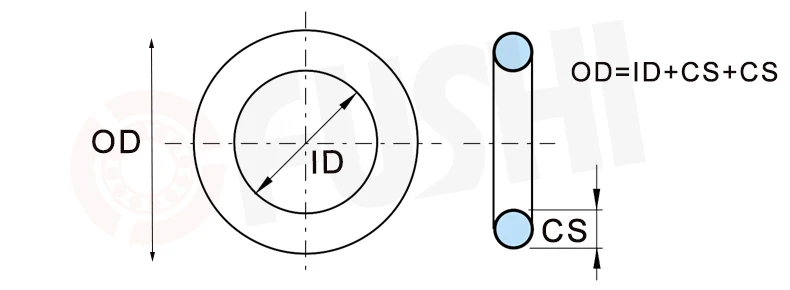

O-ring Sealing Principles

O-rings are bi-directional seals, circular in shape and cross section. O-rings are generally

made of an elastomeric material, but may be made of other materials such as PTFE or

metal. An O-ring seals through the deformation of the seal material by installation and media pressure to close off the gap between mating components. Higher system pressures can cause deformation through the gap, known as extrusion, resulting in seal failure. Choosing a harder seal material or installing back-up rings to support the O-ring may alleviate this problem.

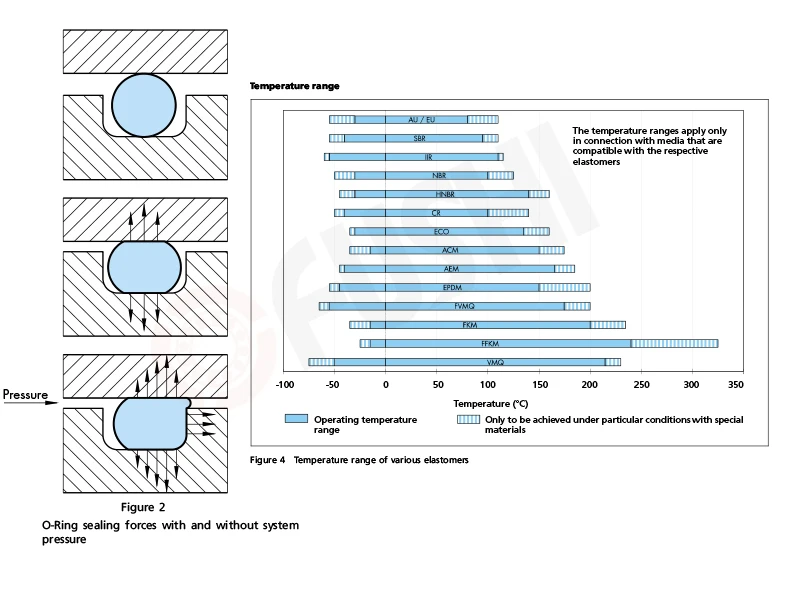

Method of operation

O-Rings are double-acting sealingelements. The inital squeeze,which acts in aradialora xial direction depending on the installation, gives the O-Ring its initial sealing capability.These forces are superimposed by the system pressure to create the total sealing force which increases as the systeme pressure increases (Figure 2).

Under pressure, the O-Ring behaves in asimilar way to a fluid with high surface tension. The pressure is transmitted uniformly to all directions.

VMQ (Silicone Ring):

It has good electrical insulation properties. Tensile strength is worse than the general rubber and not oil-resistant, silicone temperature-resistant range temperature:-43~210℃, the most outstanding advantage is that it has excellent high temperature resistance, anti-static properties, and through special formulation process, can be produced into food grade material.

Application

The O-Ring is used predominantly for static sealing applications:

- As aradial static seal, e.g. for bushings, covers, pipes, cylinders

- As an axial static seal, e.g. for flanges, plates, caps.

O-Rings in dynamic applications are recommended only for moderate service conditions.They are limited by the speed and the pressure against which they are to seal:

- Forlow duty sealing of reciprocatingpistons, rods, plungers, etc.

- For sealing of slowlypivoting,r otating or spiral movements on shafts, spindles,rotary transmission leadthroughs, etc.

FAQ

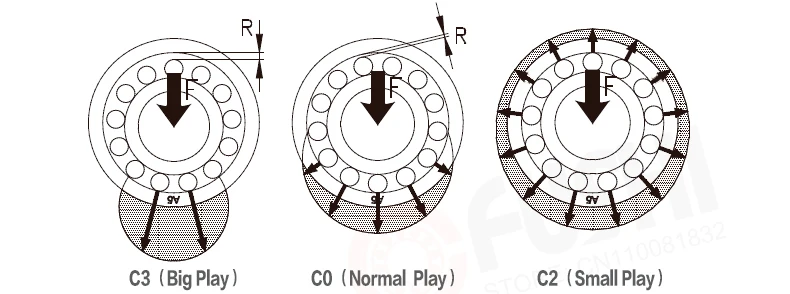

1. Why do the bearings I receive have shaking?

The clearance of the bearing is related to the play.

The default is the standard C0 clearance, which is usually 3-18um.

The corresponding principle is shown in the figure below.

If you don't need to shake, please choose C2 small clearance bearing,

If you have any questions, please contact us before purchasing.

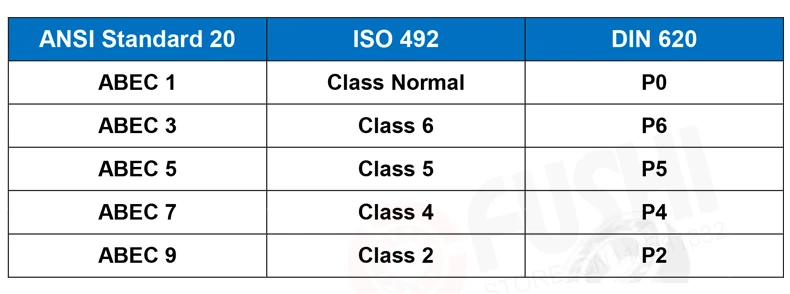

2. What is the accuracy of ABEC-1?

ABEC is the American ANSI standard.

The corresponding German DIN standard and international ISO standard are as follows:

3. Do you provide logistics tracking information?

Yes, all our products provide full logistics tracking.

And the products you buy are all new.

We will buy transportation insurance for you.

If the product is damaged or lost during transportation, you can get paid.