Introduction of the motor

1. Name of the motor : JGA25-2430 Micro BLDC DC Geared Motor 12V 24V

2. Brushless geared motor is composed of a brushless high speed motor and a gearbox to form a complete DC brushless geared motor. The life of a brushless motor is about 10 times that of a brushed motor, can greatly reduce the maintenance cost of the project. If the load of the project does not exceed the rated torque of the motor, then the motor is ideal for use in smart devices with long life requirements

3. Prominent feature : Full metal gears; long life; stable and reliable performance; low noise; support reverse; Built-in driver; With brake function; Pulse signal output; Overcurrent and stall overload protection; No sparks are generated when the motor is running; the brushless motor is controlled by the frequency conversion technology, which is more energy-efficient than the carbon brush motor.

4. Rated voltage have DC 12V and DC 24V

5. DC 12V ; You can choose the no load speed have :

14rpm/18.5rpm/30rpm/40rpm/54rpm/65rpm/88rpm/150rpm/200rpm/320rpm/700rpm/1550rpm

Rated torque between 0.12 To 7.75 ; Stall torque: between 0.4-9.28KG, it is recommended that your project load not exceed the rated torque; select a no load speed in DC 12V, there will be corresponding rated torque and stall torque, please refer to the parameter table below.

6. DC 24V ; You can choose the no load speed have :

14rpm/18.5rpm/30rpm/40rpm/54rpm/65rpm/88rpm/150rpm/200rpm/320rpm/700rpm/1550rpm

Rated torque between 0.12 To 7.75 ; Stall torque: between 0.4-9.28KG, it is recommended that your project load not exceed the rated torque; select a no load speed in DC 24V, there will be corresponding rated torque and stall torque, please refer to the parameter table below.

7. Direction of rotation of the motor: CW Or CCW ; Support Reversed

8. The shaft shape of the motor : D type, please refer to the size chart below for all dimensions of the motor.

9. The speed of the motor can be adjusted using the speed controller. This motor and speed controller are sold in combination. You can refer to the combination sales introduction below.

10. Motor DC power connection is safe; the experiment proves that the motor voltage is lower than 36V without any danger.

11. This motor is suitable for a variety of micro-automation equipment. As long as you confirm that the motor voltage and torque of your choice are suitable for the voltage and load of your project before purchase, there is no limit to the scope of use of this motor.

Wiring method introduction

Black line : Connect DC power supply negative - (Prohibit errors)

Red line: Connect DC power supply positive + (Prohibit errors)

The red wire is connected to the positive pole of the power supply; the black and white wires are connected to the negative pole of the power supply, and the motor rotates clockwise.

The red wire is connected to the positive pole of the power supply; the black wire, the white wire, the orange wire, and the three wires are connected to the negative pole of the power supply at the same time, and the motor rotates counterclockwise.

Orange line: is the line that controls the motor to rotate clockwise or counterclockwise. Connect the orange line to the black line and the motor will change the direction of rotation immediay. ( Overcurrent protection 0.8A; once the current is exceeded, the motor will stop working immediay, and the motor can be re-run after the power is connected again.)

Yellow line: Signal line, the motor rotates one turn and output 9 pulse signals

White line: Duty cycle, pulse width speed regulation 15-25khz

The following is the motor parameter table

Sincere reminder

Your project load should not exceed rated torque of the motor, otherwise the life of the motor will be reduced

The parameters in the table below are the parameters for the motor connection rated voltage 12v / 24v

If the motor is connected to a non-rated voltage input, all parameters of the motor will change.

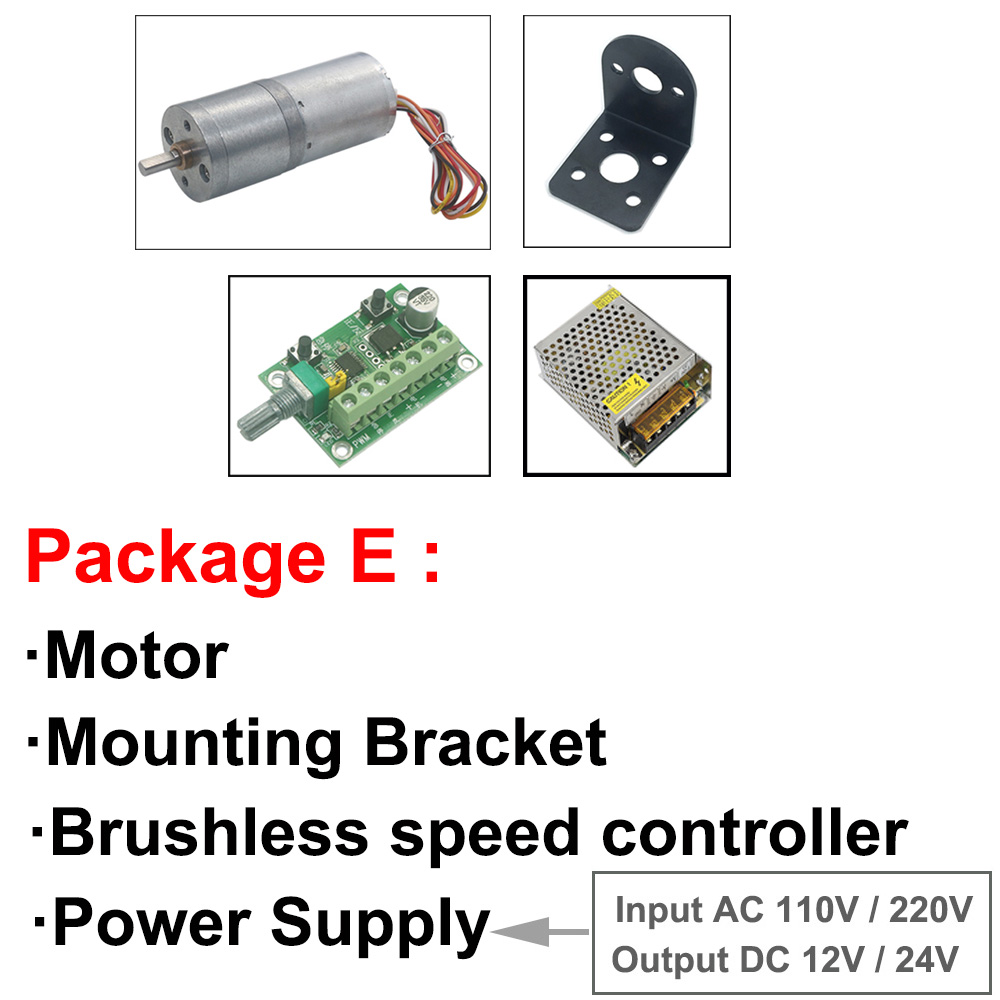

How to buy the products you need

Package A : You will receive a motor

Package B : You will receive a motor and mounting bracket

Package C : You will receive a motor and a brushless controller;

This controller can more easily control the speed of the motor; rotate clockwise or counterclockwise;

Package D : You will receive a motor ; a mounting bracket and a brushless controller;

Package E : You will receive a motor ; a mounting bracket ; a brushless controller and power supply;

For example, the voltage in your country is AC 110V Or AC 220V, but the voltage of this motor is DC 12V Or 24V, so the motor cant directly connect to your home power supply. You can solve this problem with this power supply, the input voltage of the power supply is AC 110V or AC 220V, the output voltage is DC 12V Or 24V, then the motor line can be connected to the power output DC interface

For example 1, the speed of the motor you choose 12v 14rpm and Package A ; You will receive a motor with 12v 14rpm

For example 2, the speed of the motor you choose 12v 14rpm and Package B ; You will receive a motor 12v 14rpm and a mounting bracket