KSGER STM32 OLED V2.01 Temperature Controller For DIY Soldering Station Kits T12 Iron Tips Electric Tools Auto-Sleep Quick Heat

DIY requirements and risks: DIY technical requirements, the soldering station does not provide the circuit diagram and schematic diagram, after purchase contact to obtain the installation wiring diagram, therefore, the proposed rookie, bird, bird please consider, I can only provide welding related guidance, all devices , Once welded, will not be returned, DIY risk Participants to assess their own ability and risk, problems and risks themselves. OLED digital soldering station T12 simple instructions welding station main functions and features: ~ 480C. (required calibrated). , temperature stability plusmn 2C(no load). , T12 supports all types of leader, and 6 custom head, head shield is not used (in the menu tip management enabled in your favorite leader). (Time 1-60 minutes can be set). (soft-off) (Time 1-60 minutes can be set). Main operations: , the continuous counterclockwise rotation within 1 second 3 grid, enter standby (default is 200 degrees (150-300 degrees configurable) state, if the set temperature is below 200 degrees directly into hibernation. 1.1 standby continuous counterclockwise rotation within 1 second 3 cell dormancy (soft-off), sleep (soft-off) mode, press the encoder to enter the work state. 1.2 standby state, press the encoder or clockwise, return to work status. The previous menu. , within 1 second continuous clockwise rotation 3 grid, enter the power to strengthen the current temperature of +50 degrees (10-200 degrees configurable) after 5 minutes automatic reply (1-60 minutes can be set), the You can also advance any operation encoder recovery. , short press to enter the temperature setting state. 3.1 at a temperature setting state, the rotary encoder can adjust the temperature settings of the current group, the default step is 5 degrees (settable step 1-50). 3.2 at a temperature setting, press and hold the rotary encoder and rotate, you can switch setting groups. 3.3 at a temperature setting state, short press coder to save and exit to normal. , the press encoder and turn it clockwise can enter for the first interface, this interface output is turned off, you can perform live for the first operation. You can switch the type of leader. And calls related to the head of the more positive curve. 5. Under normal circumstances, press the encoder and counter-clockwise to enter temperature than the standard interface, can be calibrated parameters for the current tip, they can be corrected to restore the default parameters. Wizard before entering more positive, more positive you need to restore the default parameters. 6. Under normal circumstances, press encoder 2 seconds to open the settings menu. 7. When all settings interface and menu, press the encoder can not save two seconds back.

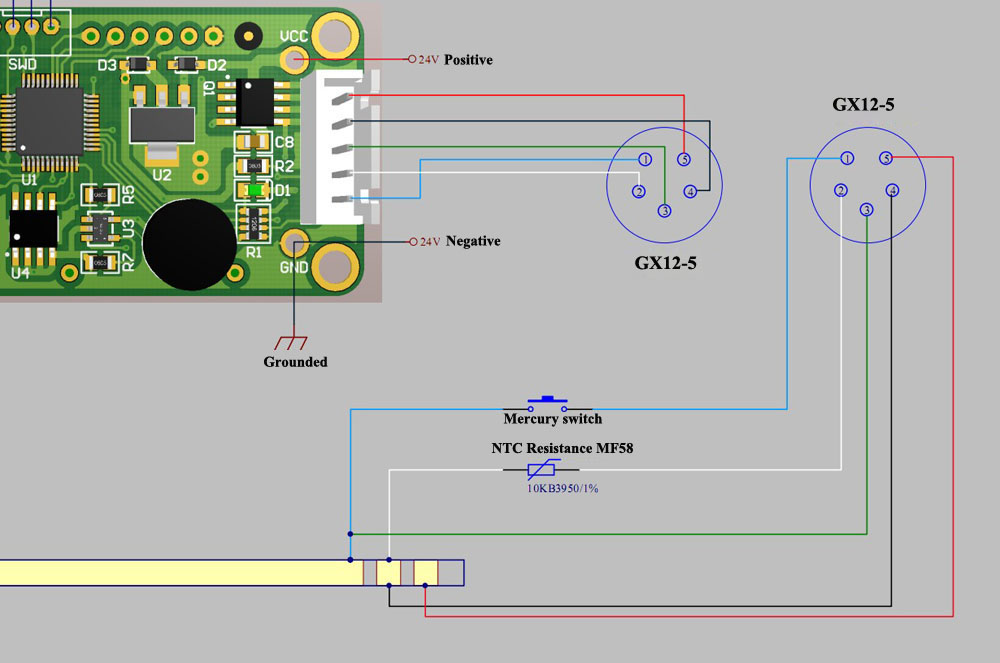

GX12-5 connector

Regarding the problem that the temperature displayed on the soldering station is not accurate with the actual temperature: Please use the soldering iron tip temperature tester (please do not use a multimeter) to test the temperature. When the soldering station is working at low temperature (less than 280 degrees), the temperature displayed on the soldering station and the actual temperature of the soldering iron tip are only for reference , which is not accurate because They are affected by the surrounding environment. The surrounding environment will carry away heat, causing the soldering iron tip to lose some heat. If using a HB tip thermometer, pls make sure the soldering iron tip is suspended at the center of the temperature sensing line. If you are very strict with temperature, please do not buy this soldering station. The problem that tin wire cannot be melted at 227 degrees. The melting point is the melting point of the substance itself. When the temperature of the substance reaches the melting point of the substance, it is possible that the substance cannot be melted. For example, the melting point and freezing point of ice are both 0 degrees Celsius, and water does not necessarily freeze at 0 degrees Celsius. Since the temperature of the substance is affected by the surrounding environment, the actual melting point of the tin wire is higher than the melting point indicated by the tin wire. If the wire is placed in a thermostat tin furnace at 226 degrees Celsius, it is possible to melt in a sealed tin furnace. If it is wrapped around the soldering iron tip, it is impossible to melt. Because there is a gap between the tin wires, and the soldering station has a temperature difference, the soldering iron will lose some heat when it heats up, and the surrounding air will also absorb heat. The melting point of lead-free wire is 227 degrees Celsius, and the room temperature is low in winter. Under the premise of calibrating the temperature of the soldering station, at least 50 degrees Celsius should be increased to offset the heat absorbed by the air, so that the heat of the wire itself can be increased to 228 degrees Celsius. About the wake of the handle Please carefully understand the working principle of the vibration switch in the handle. The ball trigger switch built in the handle, the mounting direction of the ball switch and the rolling direction of the ball inside the ball switch need to vibrate the handle when the direction of the handle is consistent. For example, when the handle is vertical Please move the handle up and down. When swinging the handle up and down, please make sure that the ball inside the handle can trigger the SW wake-up mode, and the force needs to be slightly larger. When the handle is placed horizontally, please swing the handle left and right. Please swing the handle to an angle greater than 30 degrees, so that the ball inside the handle can trigger the SW wake-up mode. About the soldering station showing of ERROR If the ERROR is displayed, the handle or the tip is not installed properly. Please use a pair of pliers to push the tip into the innermost part of the handle. Then try rotating the tip to ensure that the tab of the tip is in good connect with the inner tab of the handle. If ERROR is still displayed and the light is always on when the tip or handle is installed, please contact us to get a solution. We encourage buyers to communicate with us to solve any problems. We will do our best for each buyer.

Brand Story